Building the Initio Chassis

As with all kits of this type, there are a variety of ways to put this together. The following steps assume you will be building one of our Arduino or Raspberry Pi kits.

1 What’s in the Box?

The Initio chassis comprises the major parts:

- Base chassis with fitted motors, gearbox, battery box, switch PCB and wheel sensors

- Top plate

- 4 wheels

- 3 bags of screws (with labels)

- Wires to connect to switch PCB depending on use

- Wire tidies to keep your cabling neat

- Bag of plastic pillars and brackets

- Plastic plate to clip onto a mini-pan tilt

2. Which Screw is Which?

From left to right:

- 36 screws for mounting the general purpose stand-offs etc. (you shouldn’t need these for the basic build, but 2 are used for mounting line followers)

- Three types of screws for sensors:

- 2 wide head screws for mounting obstacle sensor brackets (one each)

- 6 small screws for mounting the pan/tilt assembly (4) and mounting the saddle clamp to the pan/tilt plate (2)

- 4 long screws for mounting the line follower support pillars (2)

- Two types of screws for upper plate and controller

- 10 small screws for mounting the Arduino or Raspberry Pi (and L298N motor board if used)

- 8 wide head screws for mounting the upper plate

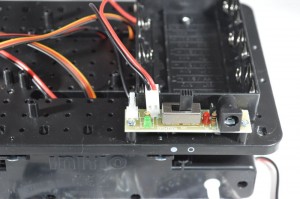

3. Connect Battery Cable to Switch PCB

** It is very important to attach this to the correct connector as shown above (labelled “batt”). Please double-check this before connecting batteries

On more recent units there are 2 connectors to the left of the battery connector on the switch board. They are both the same. Use one for the DC Jack and one for the bare-ended cables (if they are required for your build)

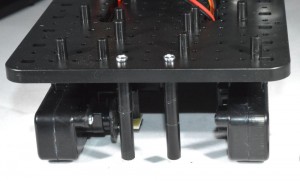

4. Fit the Line Follower Support Pillars

There are six 40mm pillars in the kit. 4 of them have flattened ends and 2 of them are straight. The 4 with flattened ends are to support the upper plate, so select the 2 straight ones for this task.

Use 2 long screws (3x12PB) from Bag2 and the 2 pillars

Screw the pillars in place. Note: you can vary the separation of the line following sensors by mounting the pillars in different holes, or to a lesser extent by twisting them once fitted

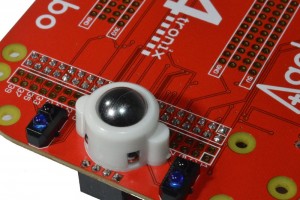

5. Fit the Obstacle Sensor Brackets

Use the 2 wide head screws (3x8PWB) and the two plastic mounting brackets

Screw the brackets in as shown above. You may want to turn them slightly away from each other so it detects obstacles off to the sides

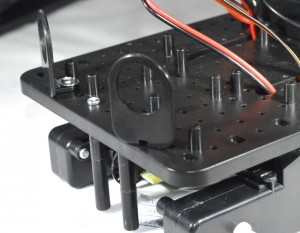

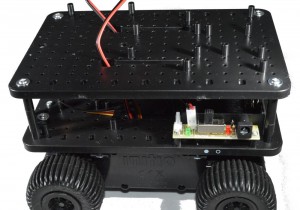

6. Fit the Upper Mounting Plate

For this we will need the 8 longer screws with wide heads (3x10PWB) and the four 40mm pillars with flattened ends

Screw the 4 pillars in tightly from underneath, ensuring that the flattened ends fit snugly into the recess in the plastic plate

Ensure the flattened ends at the top of each pillar fit into the recesses in the top plate, then use the remaining 4 screws to tighten the plate in position

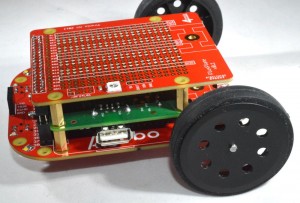

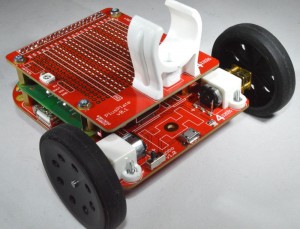

7. Chassis build is now complete

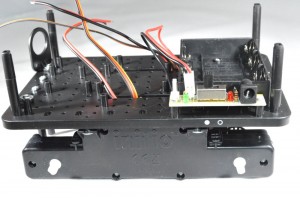

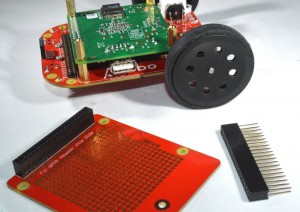

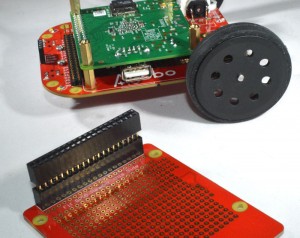

8. Fit your chosen controller

Note that there are many mounting positions that can accommodate a number of different boards from the Raspberry Pi, Arduino and other families. Depending which board is being fitted, some of the other pillars may need to be removed to avoid fouling on components underneath the boards. Simply snip off the unwanted pillars using side-cutters, nail clippers, or a sharp knife.

Some of the pillars that you are not screwing into should be left to support the board – only cut off the ones that are in the way

Use the small screws (2.6x8PB)

Fitting an Arduino

For the Uno, all 4 mountings can be used if desired. I generally use only 2

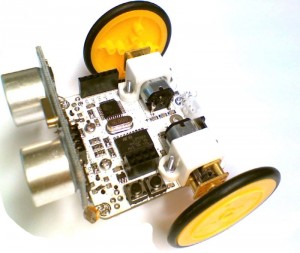

Fitting a Raspberry Pi Model B

Fitting a Raspberry Pi Model B+